From initial concepts to choosing the right plating for you to making your pins pop, we’re here for you! We work with you throughout the whole process with solid communication throughout, so that you can feel confident with the results of your badge. Worried about designing your pin or what specifications to have? Don’t worry, we offer a free design service! Our team of experienced in-house designers are here to help you every step of the way. However, if you are looking for enamel badges, we offer silk screen printing to allow more intricacies and detail. Printed badges do not have any coloured enamel fill.

4 color silkscreen press manual#

They are typically around 1mm thick, making them thinner than enamel badges, but still retaining high quality. China Manual 4 Color 4 Station Silk Screen Printing Press with Wooden Pallet, Find details about China Screen Printing Press, Screen Printing Machine from. Our printed badges are available in stainless steel or brass bases, with or without metal borders. A clear epoxy coating is added to the surface to help protect the print.

4 color silkscreen press full#

4 color silkscreen press how to#

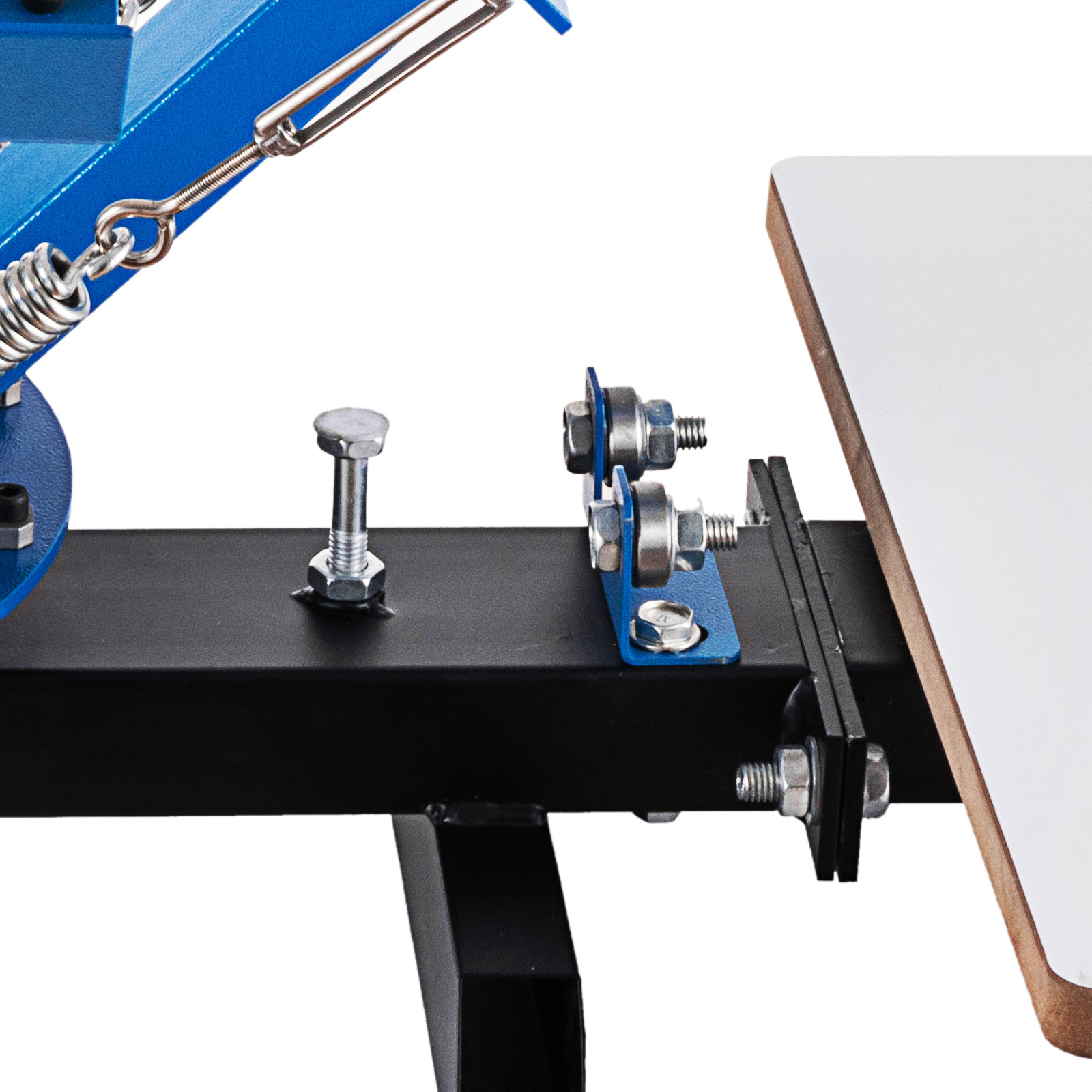

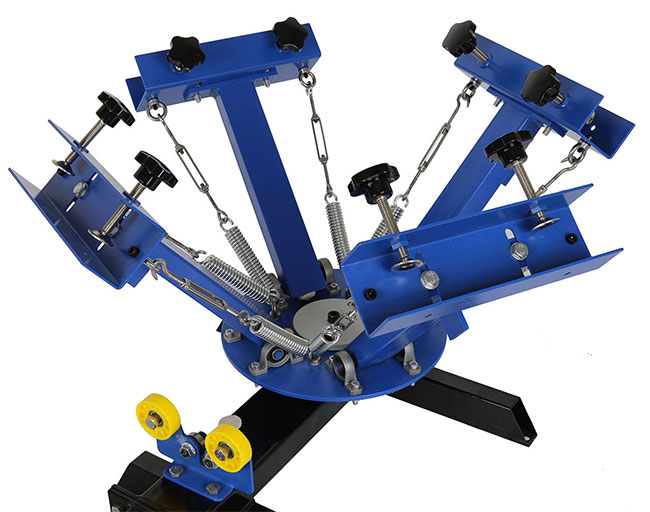

Upgraded springs to reduce spring tension and reduce spring breakages. Learn how to make a four color screen printing press, based on plans from If you want to learn how to screen print, check out.Enclosed print heads to reduce airborne lint and dust that comes between XY Micro Plates.Wider print head arm, for more print head stability.One knob off contact adjustment for faster accurate off-contact adjustment.Independent XY axis for straight line adjustment.Combined with a Torrid Flash Unit, this is an unstoppable full industrial production printing beast. Printing facility`s that print for famous brand like, Nike, Puma, RVCA, Billabong choose the X-Print. The X-Print™ is the work horse of all machines. Although this functionality makes set up between print jobs very quick and easy, it is also rock solid and supper accurate, which allows you to do the finest prints imaginable. Screen Printing Machine 4-Color 1 Station Silk Printing Kit for T-Shirt DIY with.

Steventon X-Print™ 4 – 4 color 4 station screen Printing press is in a class of its own with the tools-free, very fast, off-contact and tilt adjustments print heads. The VEVOR silk screen printing kit is easy to operate and is especially. Steventon X-Print™ 4 – 4 color 4 station screen Printing press with XYZ Micro registration has been carefully designed and engineered at world class standard.

0 kommentar(er)

0 kommentar(er)